SIZES : 3” to 36”

SIZES : 3” to 36”

CLASS : 150 to 2500;

MATERIAL GRADE : Incoloy (800, 800H, 800 HT, 825), Alloy 20; Hastelloy (C22, C276); Cupronickel Cu-Ni; Monel 400; Inconel (600, 625); Titanium (Gr. 1, 2, 3); Urea Grade; Duplex -Super Duplex F51, F53, F55, F44; Stainless steel (AISI 304, 316, 321, 347); Alloy steel (AISI Gr.1, Gr.5, Gr.9, Gr.91, Gr.11, Gr.22); Carbon steel (ASTM 105, A516/70, A350 LF2, A694 F60-65)

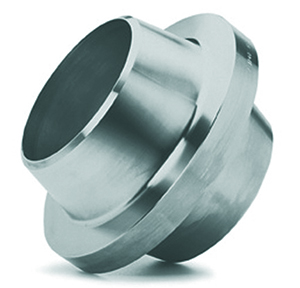

Anchor Flanges are used to anchor pipe - often when crossing streams or ravines. They are a double hub piece of steel that is put into a special holder that is part of a piling to supports the pipeline and resist loading. The anchor structure is welded to the pipe and usually embedded in concrete.

Anchor flanges actually contain axial thermal expansion – that is axial thrust in pipelines. The assumed design temperature change is 90 degrees Fahrenheit. The thrust is transferred to the anchor foundation –in which the anchor is mounted. These flanges are used at crossings and points with changes in pipeline direction.